Your specialist for lean products

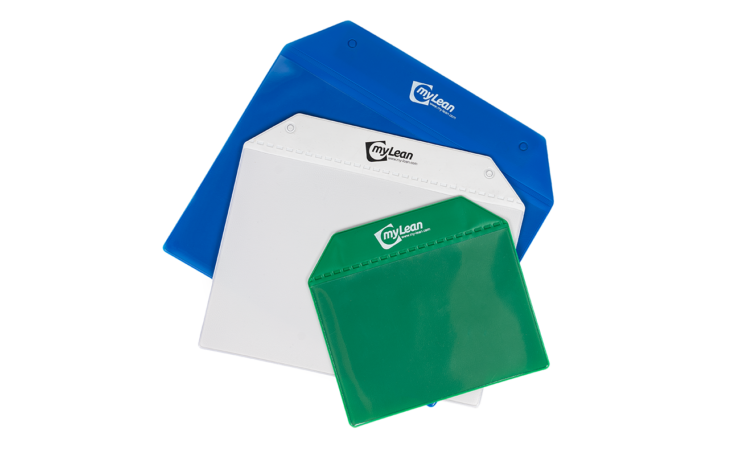

As a specialist for lean products, myLean GmbH produces and sells products for lean production. The constantly growing product portfolio includes products for the entire value chain of a company. Through the use of high-quality materials and certification according to DIN EN ISO

9001: 2015 international customers appreciate the quality of our goods. myLean products are used in many applications and different sectors. Thanks to a high level of vertical integration, large warehousing and lean processes, myLean products will be with you within a very short time. With short response times and competitive prices, we give you the joy of order and cleanliness in your workplace.

Markets that we supply

Automotive

Automotive

Logistic

Logistic

Medicine

Medicine

Aviation

Aviation

Mylean products are used in many applications and different sectors.

Thanks to a high level of vertical integration, large warehousing and lean processes, mylean products will be with you in no time at all.

With a short reaction time and prices in line with the market, we give you the pleasure of tidiness and cleanliness in the workplace.

The advantages of lean products are diverse

We make your company as efficient as possible with our lean products.

Increased efficiency

Increased efficiency

Quality improvement

Quality improvement

Cost reduction

Cost reduction

Security improvement

Security improvement

Participation & motivation

Participation & motivation

The 5S method is a lean technique used in product development and production. It brings with it numerous advantages. First, it increases efficiency by organizing and standardizing workspaces, saving time. Second, it improves quality because cleanliness, order, and standardization reduce errors and waste. Third, it leads to cost reductions through less waste in materials, labor and storage. Fourth, it increases workplace safety through regular cleaning and maintenance. And finally, it promotes employee participation and motivation because employees are involved in the improvement process. In summary, the 5S method helps increase efficiency, quality, safety and employee satisfaction while reducing costs.